Why Choose FlexiBowl® for Your Automation Project?

The FlexiBowl® feeding system can help your business enhance performance by optimizing production, improving cycle time, and increasing system lifecycle.

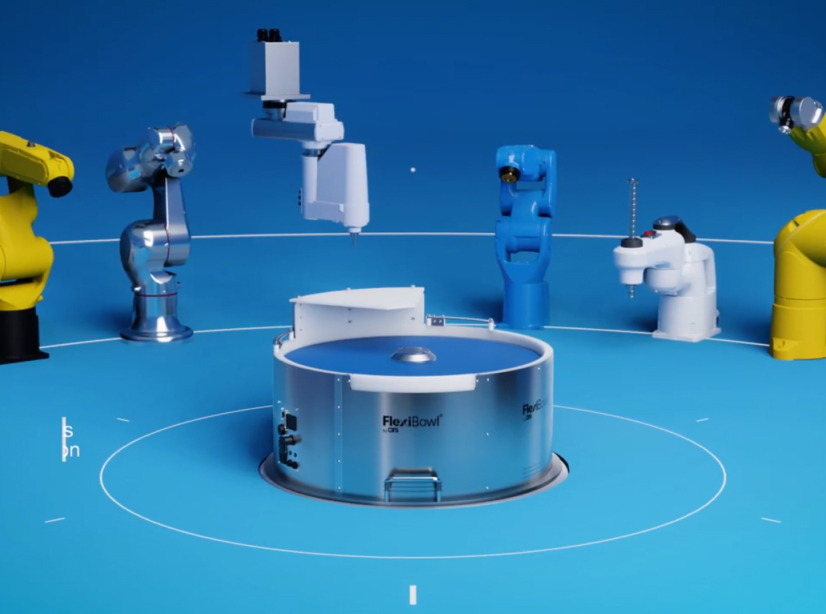

The Patented Part Feeder compatible with any pick and place robot

FlexiBowl® executes a predetermined sequence of actions, strategically designed to reduce inefficiencies. FlexiBowl® is the only parts feeding system based on a circular principle: the combined action of bidirectional rotation and pulsed actuation separates the parts to achieve optimal results.

Trusted by leading brands

The Benefits of Choosing FlexiBowl®

Discover the unparalleled benefits of our FlexiBowl® product compared to traditional alternatives. Our comprehensive comparative matrix below highlights the key advantages that set FlexiBowl® apart, including superior flexibility, enhanced durability, and innovative design.

| Feature | FlexiBowl® | Flexible alternatives | Traditional Bowl Feeders | Bin Picking | Conveyor systems |

|---|---|---|---|---|---|

| Compact layout | |||||

| Easy Integration | |||||

| Suitable for small components <10mm | |||||

| Lead time 4 weeks | |||||

| Frequent Production changeover | |||||

| Throughput >=60ppm | |||||

| Suitable for large components <300mm | |||||

| Complex components* |

The solution for your feeding project

With over 30 years of experience, we can quickly respond to the most specific needs of those who choose automation.

We support companies from the preliminary analysis to the choice of the most suitable solution, accompanying the customer in the various phases. With full teams dedicated to research and development of new technologies, we aim to provide solutions to improve the production efficiency of companies around the world.

Our products and available range

FlexiBowl® orients and separates parts and can be integrated with any vision system and any robot for parts feeding. The FlexiBowl® system is highly versatile, capable of feeding parts between 1 and 300 mm and from 1 to 300 g, regardless of

- Geometry

- Surface

- Material

Its lack of product-specific tooling and its easy-to-use and intuitive programming permit quick and multiple product changeovers even during the same work shift.

TEST CENTER

Our Test Center video reports allow you to see the system in action with the components it will actually handle, to precisely identify the optimal model and optional accessories. The feasibility test is free and is concrete proof that helps you make the right choice to get the most competitive solution.

SERVICE

We provide support at all stages: from the choice of system, to shipping, set up, start up and during operation and changeovers. Routine maintenance is drastically reduced compared to traditional technologies. Our goal is for you to feel self-reliant but never alone.