Sliding carriage assembly with flexible part feeding

Case Study: Automated assembly for sliding carriages: flexible feeding, DENSO robots, vision; up to 600/400 pcs/hour with consistent quality.

Our Partners

BBS Robot is an Italian company specialized in the distribution and technical support in the field of industrial robotics and automation. In particular, the company provides industrial robots, cobots (collaborative robots), and components for advanced automation in Italy.

GHECOR is a company that operates in the industrial Automation sector, specialising in the design and construction of Automatic Machines for Assembly, Dimensional Controls and Mechanical Processing. Founded in 1999 after ten years of experience in the sector, thanks to the collaboration of our I.T., mechanical and electronic technicians, GHECOR produces special machines twhich reduce labour costs and minimise production times.

The Challenge

- Feed complex metal brackets unsuited to traditional systems, ensuring reliable orientation and positioning for coupling with wheels.

- Maintain high productivity across multiple variants (single-wheel/double-wheel) while reducing setup times and downtime.

- Embed inline quality (inspection and lubrication) in a compact layout with full process traceability.

The Solution

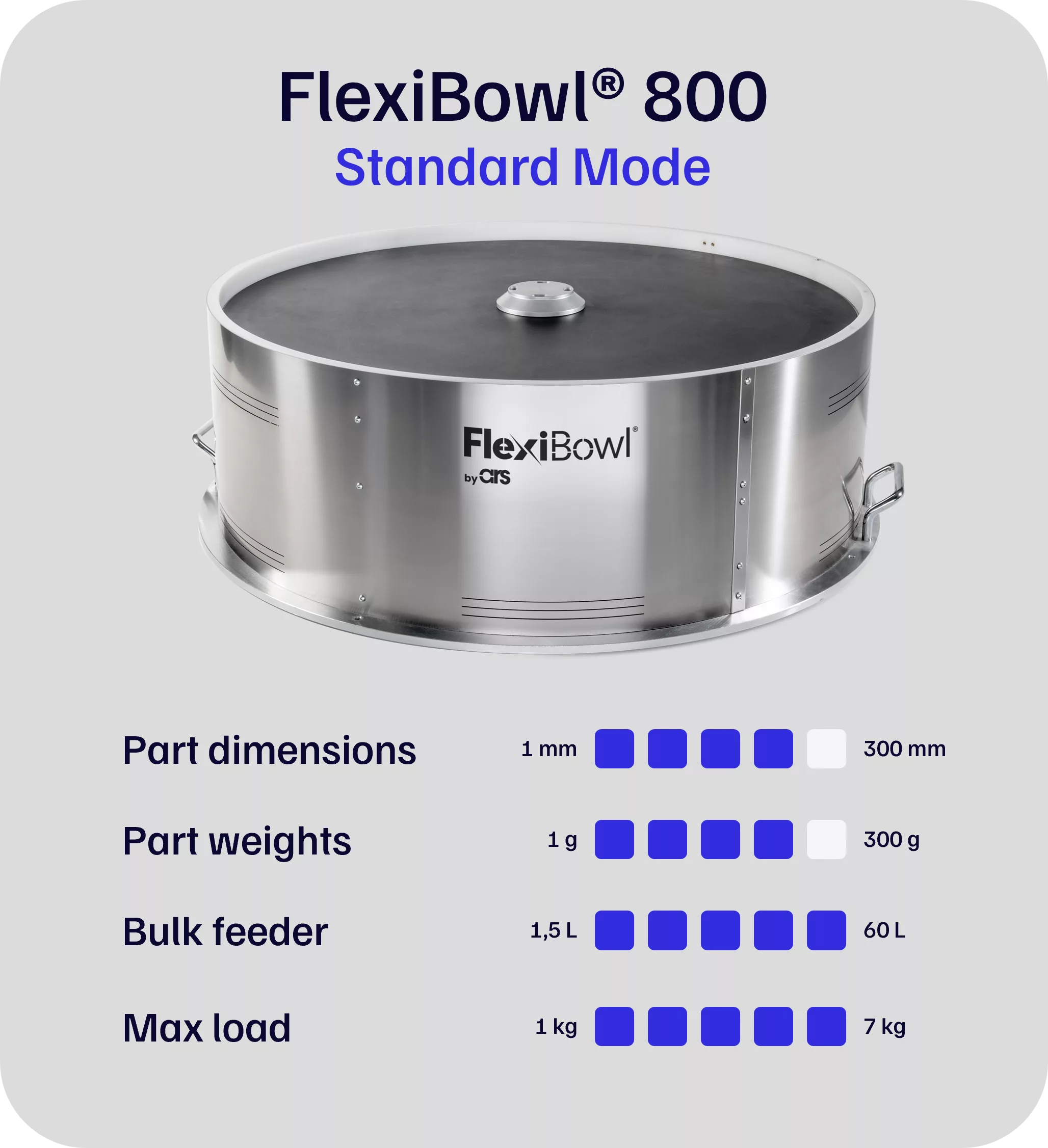

- FlexiBowl® 800 feeds complex-geometry brackets; the 6-axis robot picks and places them into assembly jigs.

- 2 DENSO LPH040 SCARA robots for fast, accurate handling in the service steps.

- Compact anthropomorphic DENSO VS6577 for complex tasks and FlexiBowl®/jig management.

- 2 vision systems verify the presence and conformity of balls inside the wheels.

- 3 automatic greasing stations before final assembly; modular, compact layout enables quick changeovers.