Discover 4 alternatives for Parts Feeding Systems with our infographic. Optimize production with flexibility and efficiency. Our infographic reveals 4 alternatives for Parts Feeding Systems, empowering you to optimize production with flexibility and efficiency. The dynamics of increasing market complexity push companies to innovate products and processes for Parts Feeding Systems. Download the Infographic for...

Leading Medical Equipment Assembly Solutions Top companies in the medical equipment assembly field are innovating. They’re creating solutions able to produce multiple product types simultaneously. This delivers the flexibility of small batches without productivity loss. Automation and Efficiency in Cleanroom settings A new generation of robots and flexible feeding systems is emerging. Designed for cleanroom...

GM Automatyka has presented our FlexiBowl solution at ITM Industry Europe in Poznán with their vice-president Mateusz Gierczak. The video below showcases the best features, including super-fast feed rate and multi-feed mode, where FlexiBowl handles different types of components at the same time. ITM INDUSTRY EUROPE 2021 Poznań ITM INDUSTRY EUROPE is the leading trade...

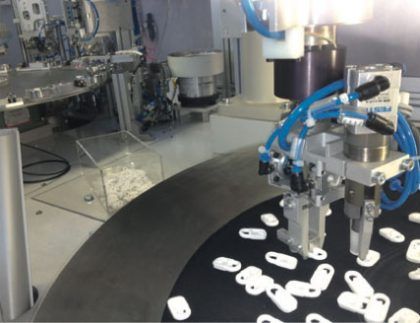

Flexible feeders are vision-based technologies for factory automation that provide manufacturing plants with the possibility to adjust production volumes and spread batches in different machines with minimum set up time. The flexible feeder is a component of a larger system which includes a robot, a vision system and a bulk feeder. Parts are stored within...

Vibratory Bowl Feeder: Traditional part feeding system FlexiBowl: the new frontier of feeding systems Comparing FlexiBowl® and Vibratory Bowl feeders Vibratory bowl feeders: application fields FlexiBowl: the alternative to traditional bowl feeders Related articles Vibratory Bowl Feeder: Traditional part feeding system Vibratory Bowl feeders are the most common solution to handle and sort bulk products...

Total cost of ownership We explain below why FlexiBowl® is a cost-effective solution, according to current performance indicators. Asset Lifecycle Management (ALM) is a management approach for industrial equipment which mainly addresses use and maintenance phases but also design, manufacturing, installation and dismissal/recycling phases. Within ALM, particular attention is given to the TCO (Total...

What is a SCARA Robot? The SCARA acronym stands for Selective Compliance Assembly Robot Arm or Selective Compliance Articulated Robot Arm. Scara is a type of Industrial robot. The SCARA robot is most commonly used for pick-and-place or assembly operations where high speed and high accuracy is required. Generally a SCARA robot can operate at...

A PC based vision software package FelxiVision is a PC based vision software for robot guidance that can be optionally supplied with FlexiBowl feeding systems. FlexiVision is a vision software based on Cognex library, compatible with a large variety of industrial robots and the main purpose is to allow the deployment of flexible feeding cells...

The flexibility of a system describes its ability to adapt to a wide range of possible environments. Flexibility in manufacturing is the ability to reconfigure manufacturing resources in order to efficiently produce a range of products of acceptable quality. The concept of flexibility comes from the Japanese philosophy of “lean manufacturing,” which for many decades...

Integrators who manufacture assembly automation and OEM’s who need equipment to manufacture assemblies are faced with a very large challenge of how to get the parts into the assembly machines for the assembly process, minimize workcell requirements, and keep costs down. Whether there is a need to increase productivity, reduce costs or add product variants,...