Leading Medical Equipment Assembly Solutions

Top companies in the medical equipment assembly field are innovating. They're creating solutions able to produce multiple product types simultaneously. This delivers the flexibility of small batches without productivity loss.

Automation and Efficiency in Cleanroom settings

A new generation of robots and flexible feeding systems is emerging. Designed for cleanroom assembly, these systems enhance efficiency and automate production variations. Specifically, feeding systems for flexible industrial production in cleanrooms tackle difficult challenges. Some of these challenges were almost impossible to solve using traditional methods.

Savings and Efficiency in Cleanroom Facilities

For cleanroom-based facilities, these solutions are game-changers. They generate savings, boost plant efficiency, and allow for production adaptation to shifting requirements. Remarkably, all this is achievable without system modifications.

New Flexibowl® Compatible

Production of small batches with the same efficiency as large ones

Introducing FlexiBowl®: ISO 5 Compatible Solution for Cleanroom Settings

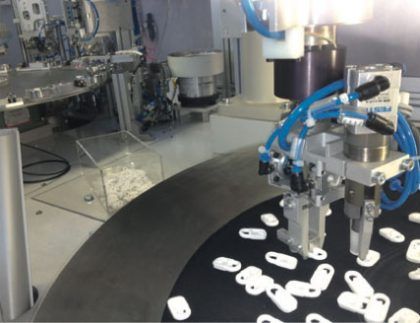

Efficient small batch production is no longer a dream, thanks to flexible solutions like FlexiBowl® for feeding medical components. Robotic automation in cleanrooms allows the production of small medical procedure kits and devices at large-scale efficiency.

Maximized Production Speed in cleanroom settings with FlexiBowl®

With FlexiBowl® by Ars Automation, separate material flows can be sorted for maximum production speed. This applies to small batches of items such as medical devices, kits, custom packages, and various syringes. By reducing operating costs and manual intervention, it boosts productivity.

Versatility and Capacity of FlexiBowl®

FlexiBowl® offers adaptability through vision systems. It accommodates all components with sizes from 1 mm to 250 mm and weights between 1 g and 250 g. New products or packages can be configured with minimal production interventions. Thanks to recipe programming, it allows a maximum load of 7 kg, paired with hoppers ranging from 1.5 l up to 40 l.

Certification and Compliance of FlexiBowl®

Designed for flexible production systems, FlexiBowl® meets high standards. It complies with cleanroom standards up to ISO 5, which corresponds to FED-STD-209E's Class 100, in accordance with EN ISO 14644-1.