PRODUCTS

We can help you choose the best options for your components

FlexiBowl®: Ars Automation's

Parts Feeding System to separte and sort components

Ars Automation has extensive know-how in the industrial automation field. With over 35 years of experience in more than 40 countries, we have developed a unique parts feeder system with numerous optional accessories to deliver the simplest solution for parts feeding.

Our engineers and experts have successfully developed Flexibowl: a revolutionary system that makes the task of feeding parts into a production line faster and more performing. The system's flexible design makes it possible to separate different sizes and shapes of materials, while its reliable performance provides an easy way to feed components.

Vision-Based Parts Feeding System: parts picking and placing solution

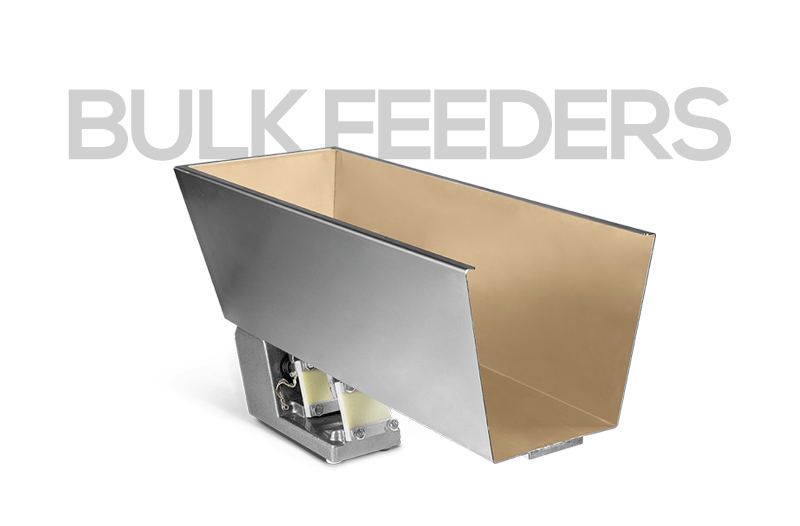

The market's available vision systems are simple to integrate with our solution, and, as if that wasn't enough, our vision system provides an accurate reading of all incoming parts. Finally, we also supply an assortment of hoppers.

We consider integration essential: we design our products to easy-communicate with other technologies on the assembly and manufacturing lines. Indeed our solution can interface with third-party technologies and are suitable for production systems that utilize industrial robots or cobots. Moreover, our product range is easy to install on any size or type of production line.

Using accessories and available options, you can quickly adapt our versatile component feeder to match changes in production demands. Greater integration, applicability, and success for the automated separation, orientation, and sorting of parts are made possible by a wide range of configuration parameters.

The result is a high-level of flexibility, reduced cycle times, and increased productivity.

ASK FOR A FREE TEST

Enhance Productivity and Precision in your Assembly Line with Ars Automation's Parts Feeding System

Our Project Office will use the information you enter to formulate a configuration proposal specific to each component you intend to process.

FlexiBowl® parts feeding system

Easy Integration with Robots and Co-bots

FlexiBowl's unique design and advanced technology allow for effortless integration with a wide range of industrial robots and collaborative robots (co-bots). Thanks to our cutting-edge Plug-In system, incorporating FlexiBowl into your existing assembly and manufacturing lines is effortless.

Premium Plugin Robot

Fanuc | FlexiExpert

Universal Robots

Easy Robot Plugin

ABB

Denso

Doosan

Epson

Fanuc

Kawasaki

Kuka

Mecademic

Mitsubishi Eletric

Omron

Staubli

TM

Yaskawa

PLC Plugin

Allen-Bradley PLC Plug-in

Omron PLC Plug-in

Siemens PLC Plug-in