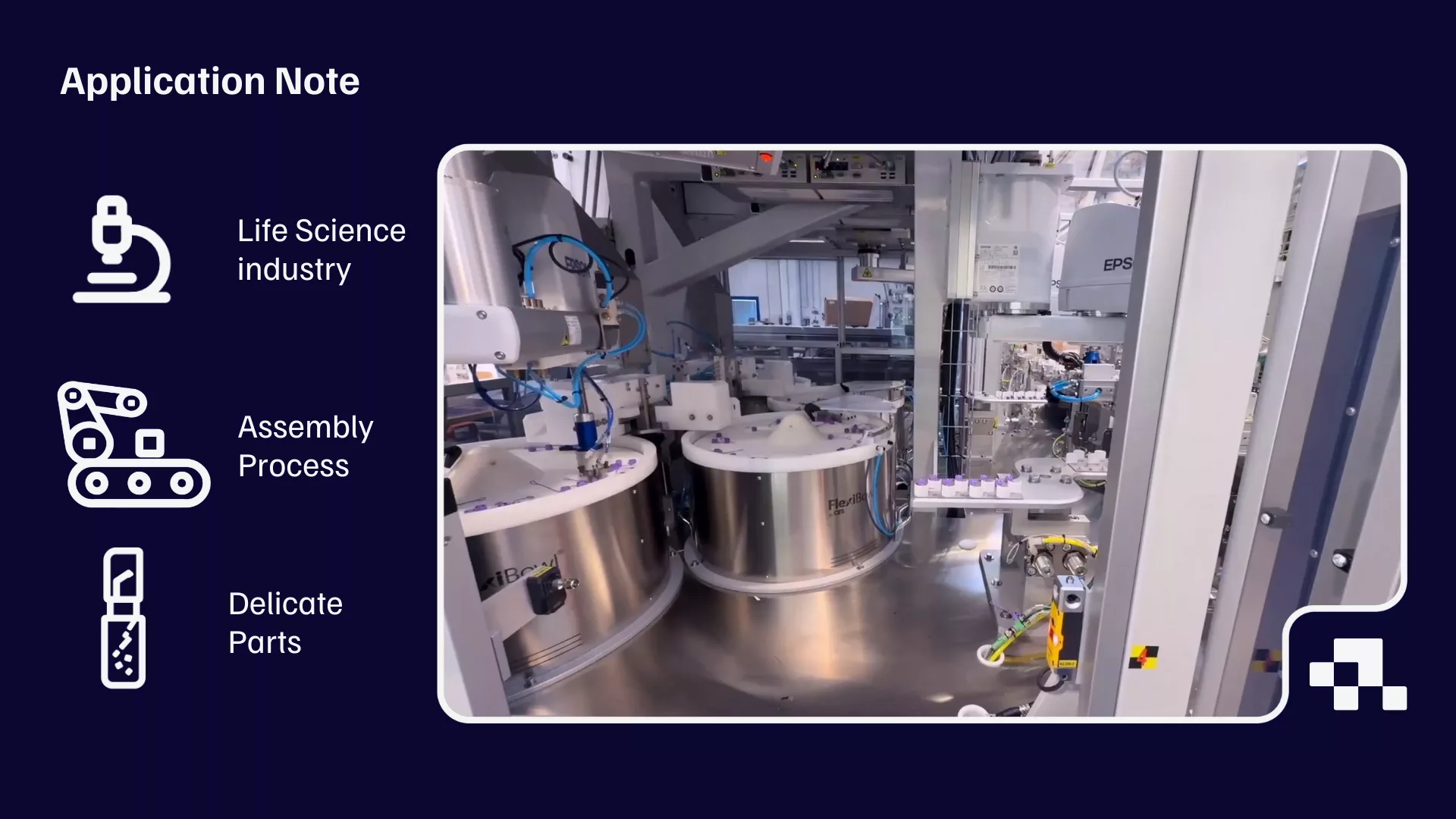

Automated assembly cell for blood-line circuits with flexible feeding and Epson SCARA robots

Case study: a system dedicated to the assembly of blood-line circuits, medical devices that require delicate handling

Our Partners

SINTA is an Italian company specializing in the distribution of components for industrial automation and robotics, with over 20 years of experience in the market. It offers state-of-the-art solutions for sectors such as automotive, electronics, packaging, food, cosmetics, and medical.

Tecnoideal is an Italian company specialized in the design, manufacture, and supply of automated machines and solutions for the production of single-use medical devices. Since 1981, it has been developing technologies for production processes, assembly, testing, and custom industrial automation, supporting Italian and international customers with semi-automatic machines, fully automated production lines, and pre- and post-sales support services.

The Challenge

- Handle soft medical-grade silicone tubes, prone to deformation and tension issues.

- Feed plastic caps with an extremely thin lanyard that can assume variable positions, while preventing overlaps and jams.

- Meet a 1-second-per-piece cycle time on a dual line with 11 stations per machine , processing up to four products in parallel, with scrap rates below 2% and full traceability.

The Solution

- Two automatic lines with 11 stations each, , designed to process four products in parallel and achieve a 1-second cycle time per piece.

- FlexiBowl® 500 flexible feeding systems dedicated to plastic caps with lanyards, combining impulse and rotational motion with machine vision to ensure reliable, jam-free orientation.

- 24 EPSON GX8 and RS4 SCARA robots: GX8 units orient the caps on the FlexiBowl®, while RS4 robots pick the oriented components and place them onto satellite tables operating in a dual cycle.

- Additional SCARA units for tube handling, repositioning the silicone lines to achieve the final shape required by the blood-line circuit.

- Dedicated tube unwinding and handling units with four unwinders that load, feed, and detension the tubes to ensure stability during the winding phase.

- Automatic gluing stations equipped with vibratory feeders and pick-and-place systems for inserting and bonding Luer connectors onto pre-wound tube sections.

- Final shaping module and cohesive paper wrapping , producing a semi-finished product ready for packaging.

- End-of-line quality control via vision inspection systems that verify dimensional and assembly integrity, with automatic rejection of non-conforming parts.

- Scalable and modular architecture, , designed for future product adaptations through simple software updates and quick gripper changeovers.

The Benefits

- Speed: a 1-second cycle time per finished product, enabled by a four-process architecture and the use of 24 coordinated SCARA robots.

- Quality: jam-free feeding of lanyard caps, in-line inspection, and scrap rates below 2%..

- Flexibility: simultaneous handling of multiple product variants with fast format changeovers.

- Reliability: a modular dual-line layout with 11 stations per machine, ensuring production continuity and reduced downtime for maintenance.