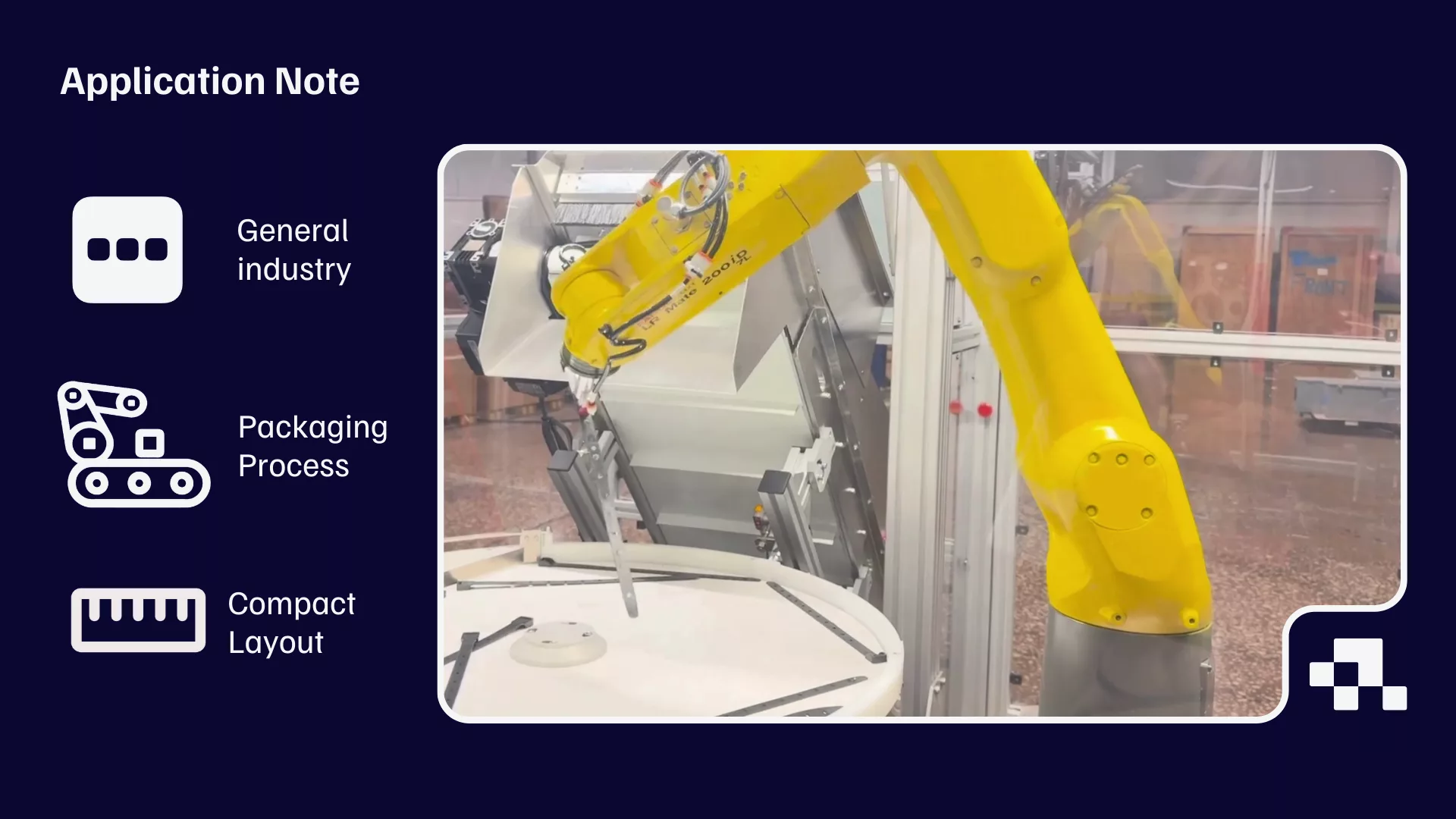

Large-size plastic cable ties automatic kitting system with FlexiBowl® 800 and FANUC robot

Case Study: Automated kitting system for plastic cable ties: flexible feeding, compact layout, and robotic integration

Our Partner

Edgewater Automation designs and builds tailored advanced automation solutions, developing high-performance machines and cells for assembly, testing, handling, and kitting processes. Their platforms ensure reliability, scalability, and seamless integration within production lines.

The Challenge

- Handle long, flexible plastic cable ties that tend to overlap, ensuring stable singulation and correct part presentation.

- Achieve continuous feeding for the kitting process, ensuring a constant flow in a compact layout that requires no manual intervention.

- Ensure maximum flexibility for future changes or expansions of the kitting process, allowing quick integration of new variants or components without structural redesign of the cell.

The Solution

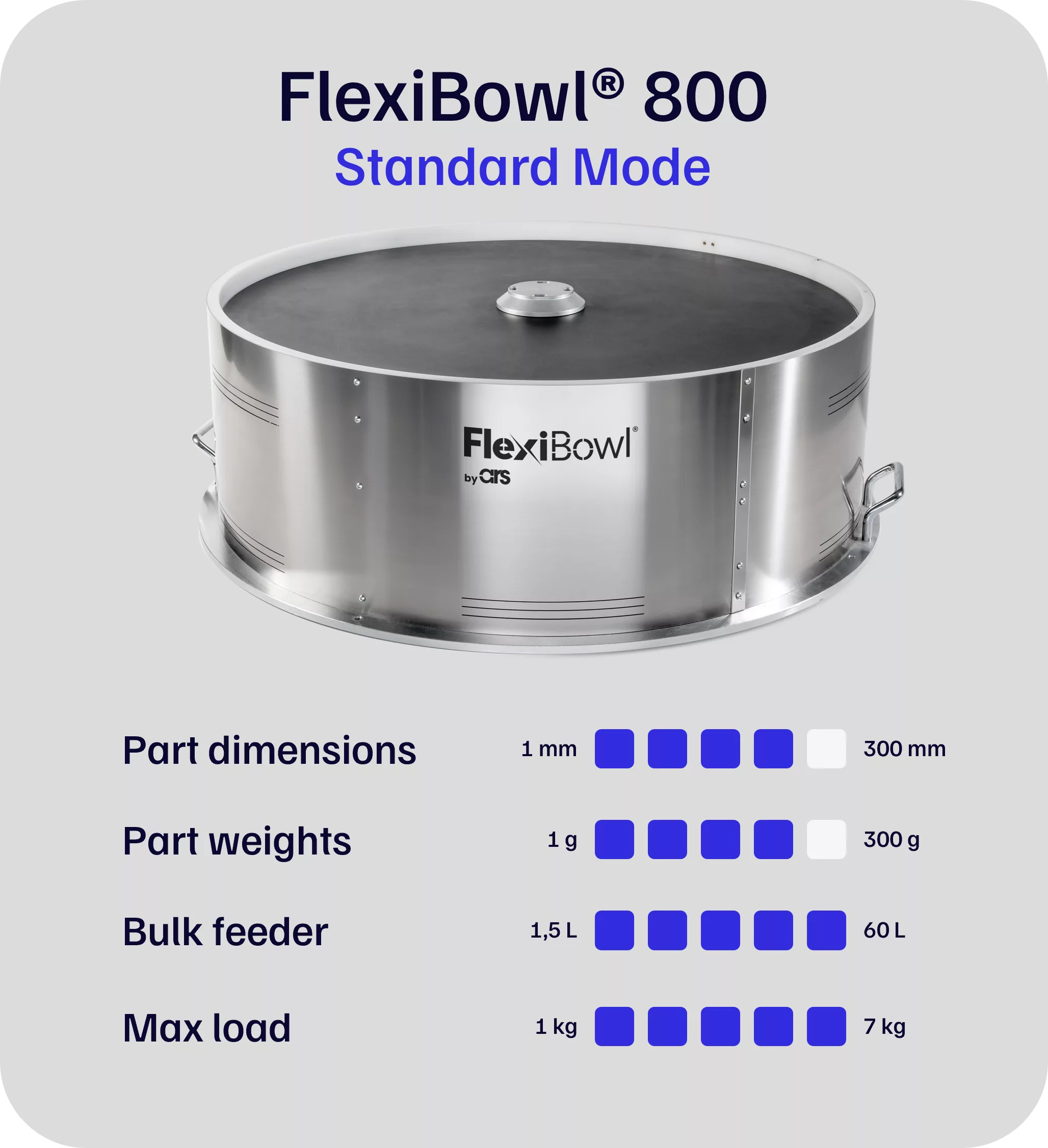

- FlexiBowl® 800 uses a combined motion of impulses and rotation to separate and distribute the plastic cable ties, reducing overlaps and tangles.

- The FANUC LR Mate 200iD robot performs precise pick & place operations, fully synchronized with the vision system to pick only correctly singulated parts.

- The 2D iR Vision system detects the position and orientation of the cable ties on the FlexiBowl® surface.

- The conveying system transfers the selected cable ties to the kitting and packaging area, maintaining a compact and orderly layout.

The Benefit

- Precision: accurate detection of position and orientation ensures stable picking, even with flexible cable ties prone to overlapping.

- Quality: repeatable and controlled feeding maintains a consistent part flow and improves the overall reliability of the kitting process.

- Flexibility: the system can quickly adapt to future changes, new variants, or different configurations without requiring complex modifications to the cell.

- Compact layout: reduced footprint and optimized integration enable efficient use of production space and simplify cell management.