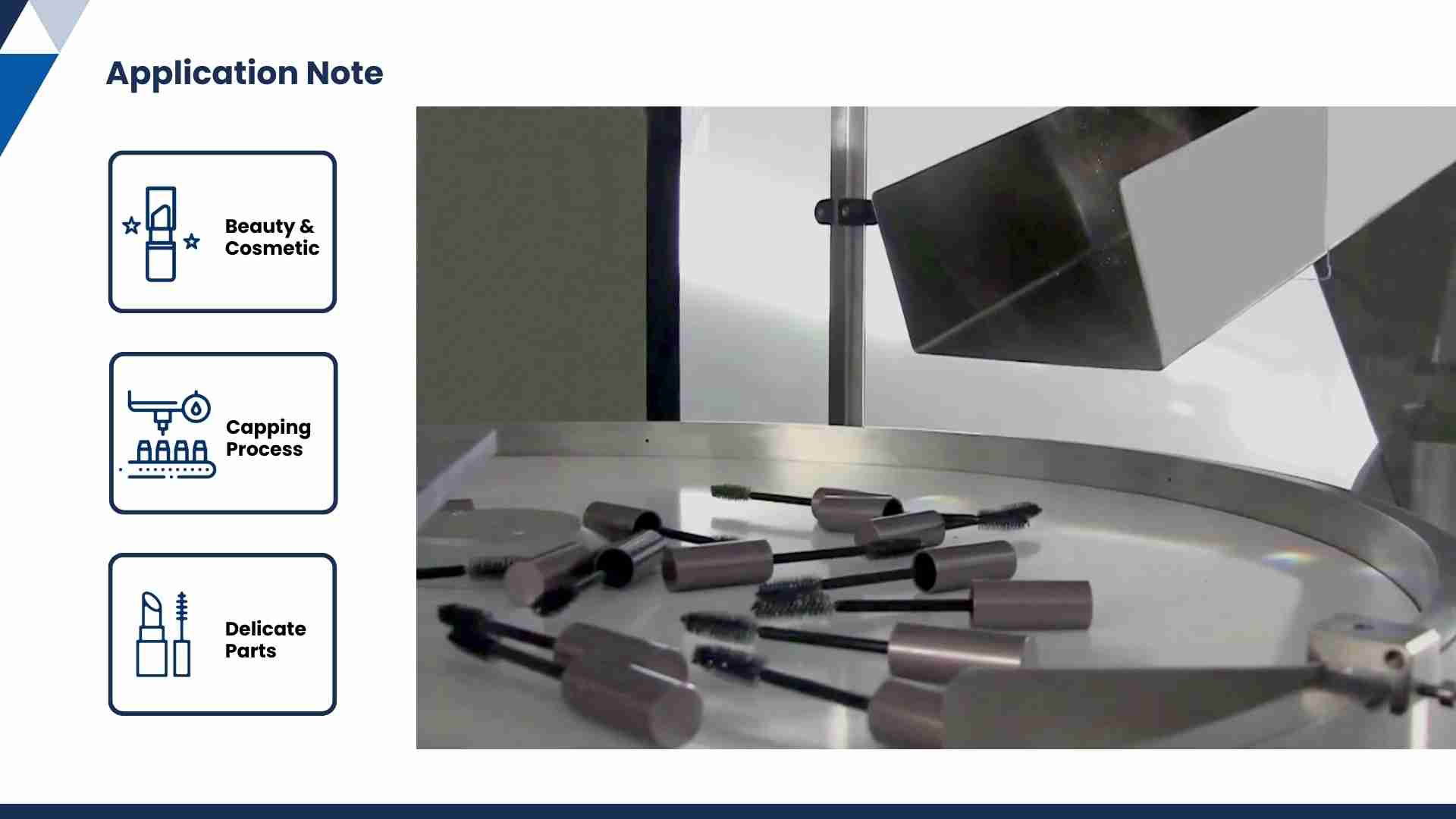

Efficient Handling of Pre-assembled Mascara Brushes in the Cosmetics Industry

Case study: how to feed brushes to a Scara robot for vertical insertion into a deposit on the rotary table, simplifying the loading of a capping machine.

Our partner

Luigi Giudici founded OMG in 1973. This was a mechanical workshop company dedicated to the manufacturing of filling systems suitable for installation into existing packaging machinery. Soon afterwards it was joined by OMAS TECNOSISTEMI that quickly became a leader in the designing and manufacturing of fully automatic filling and capping machines for cosmetic, pharmaceutical, beauty-care, biotech, chemical and food industry.

Today both companies are managed by Savino Giudici and located in Cerro Maggiore. They boast a staff of specialized engineers commited themselves to match any customer requirements.

The Challenge

- Automate the loading process of a capping machine.

- Handle delicate products such as mascara brushes, which have complex geometries and are prone to overlapping.

- Implement a system capable of flexibly adapting to the fluctuating demands of the cosmetics market.

The Solution

- Partnership with Omas to craft an innovative solution tailored for the cosmetics industry.

- Introduction of FlexiBowl® 650, a flexible feeding system that can gently separate and orient mascara brushes.

- Integration of a Scara robot with end-of-arm tooling to enhance precision during product pickup.

The Benefit

- Automation of the traditionally manual process of loading a capping machine, leading to higher profits and ROI.

- Reduction in potential handling errors, leading to increased production efficiency.

- Preservation of high-quality standards, ensuring minimal damage to pre-assembled products and maintaining consistent product integrity.

- Offering a scalable solution that can be adapted for various product types within the cosmetics industry.

Abstract

The cosmetics industry, characterized by unpredictable demand and constantly changing product lines, often requires frequent adjustments to production batches. This unpredictability complicates the production planning process.

As for feeding the parts, the challenge becomes even more significant when dealing with smaller items, especially mascara brushes. These brushes are delicate and prone to overlapping, making them a challenge for traditional feeding systems. As a result, many companies still rely on manual loading methods. Recognizing these industry needs, a prominent cosmetics company collaborated with Omas to refine its production process. The outcome was the incorporation of the FlexiBowl®, a flexible feeding system, to enhance the capping machine's loading procedure. The system delicately separates the mascara brushes and feeds them to a Scara robot which performs the pick-and-place operation, ensuring the brushes are systematically placed vertically into a deposit on the rotary table. This automation not only increased overall efficiency but also reduced errors, guaranteeing minimal damage to the pre-assembled items and ensuring consistent product output.