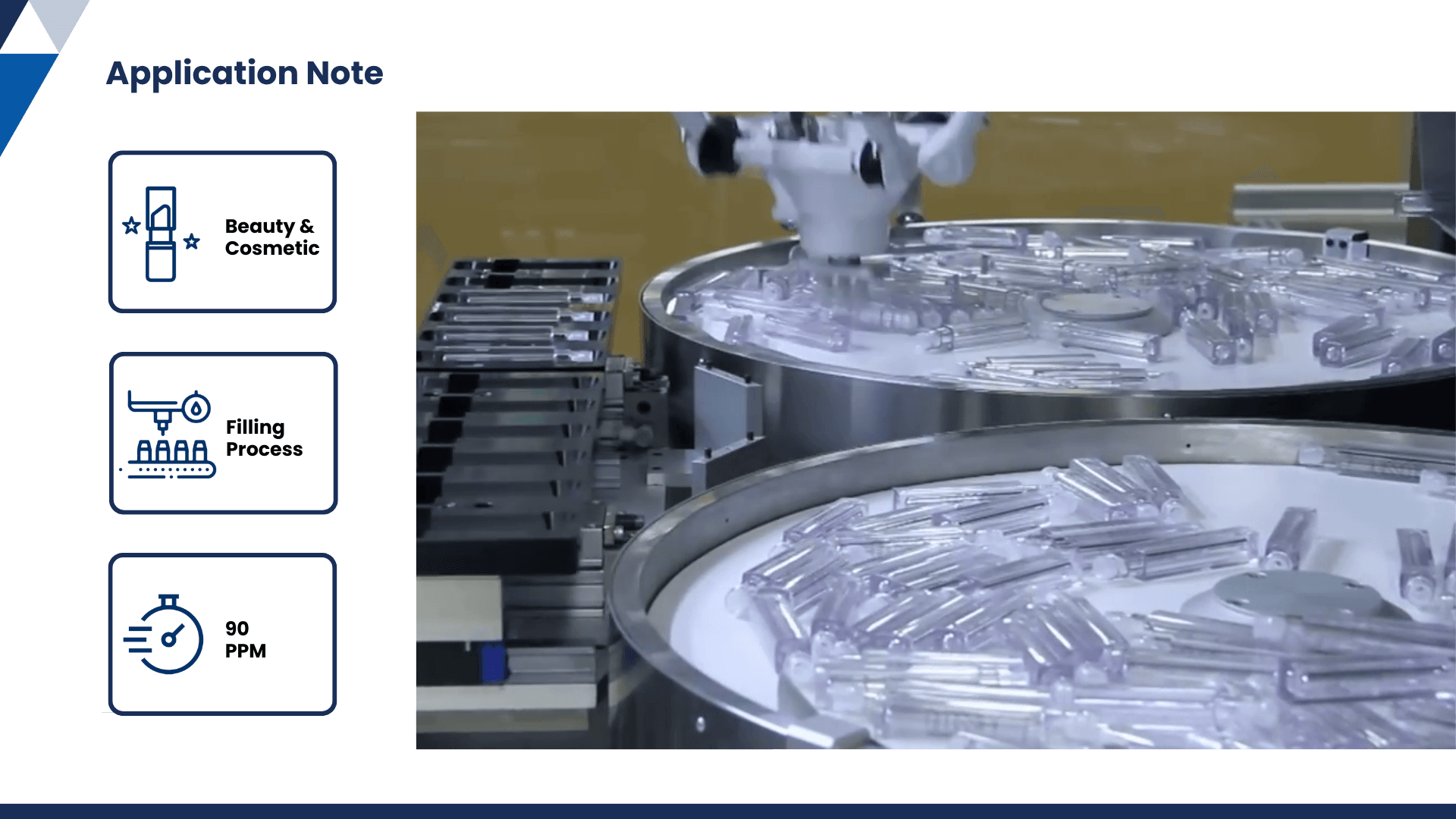

Enhancing beauty and cosmetic production

Case study: a flexible feeding solution applied to a filling process.

Our partner

Clear Automation is a leading robotic systems integrator specializing in flexible industrial automation techniques. Clear Automation’s key strengths include Industrial Robotics, Automation Design, Machine Vision, PLC’s, Line Tracking, and custom PC Applications which are deployed to assemble, inspect, label, laser mark, dispense, and package products. Industries served include Cosmetics, Personal Care Products, Medical Devices, Pharmaceuticals, Automotive, Aviation, Food and Beverage, Consumer Packaged Goods, Consumer and Industrial Electronics, and Industrial Processes.

The Challenge

- Develop a feeding solution for a lip gloss filling machine that can achieve a rate of 90 products per minute.

- Handle transparent products, a significant challenge in terms of product recognition.

- Ensure precise orientation and placement of bottles for successful filling.

- The system needs to be adaptable to accommodate different products of similar sizes.

The Solution

- Utilize a bulk hopper that feeds into two FlexiBowls® to supply a single robot designed for product orientation and placement.

- Designate the first FlexiBowl® as the main product supplier, while the second Flexibowl serves as backup.

- Use FANUC M-2iA/3SL for picking and placing the bottles horizontally and FANUC LR Mate 200iD for rotating the bottles vertically.

- Integrate the FANUC IRVision system to recognize the shape and size of the bottles, ensuring accurate placement on the production line.

The Benefit

- The system maintains a high production rate and improves efficiency.

- It manages the products delicately, minimizing the risk of damage.

- The FlexiBowl® enables the system to feed different products, regardless of their material type and surface treatment. It is highly versatile, capable of handling different products of similar size, including transparent products.

- The client can redeploy it when new models become available, optimizing the investment in machinery.

Abstract

This case study presents a feeding solution for a lip gloss filling machine, achieving a rate of 90 products per minute, realized by our partner Clear Automation. The system consists of a bulk hopper that feeds into two Flexibowls®, which are used to feed a single robot for product orientation and placement.

The main challenge in this system was the recognition of a transparent product. However, with the use of FlexiBowl® combined with the Fanuc IRVision system, the orientation of the bottles was done precisely and accurately. The vision system is designed to recognize the

shape and size of the bottles and ensure accurate placement in the production line.