Efficient handling of delicate and transparent products prone to rolling.

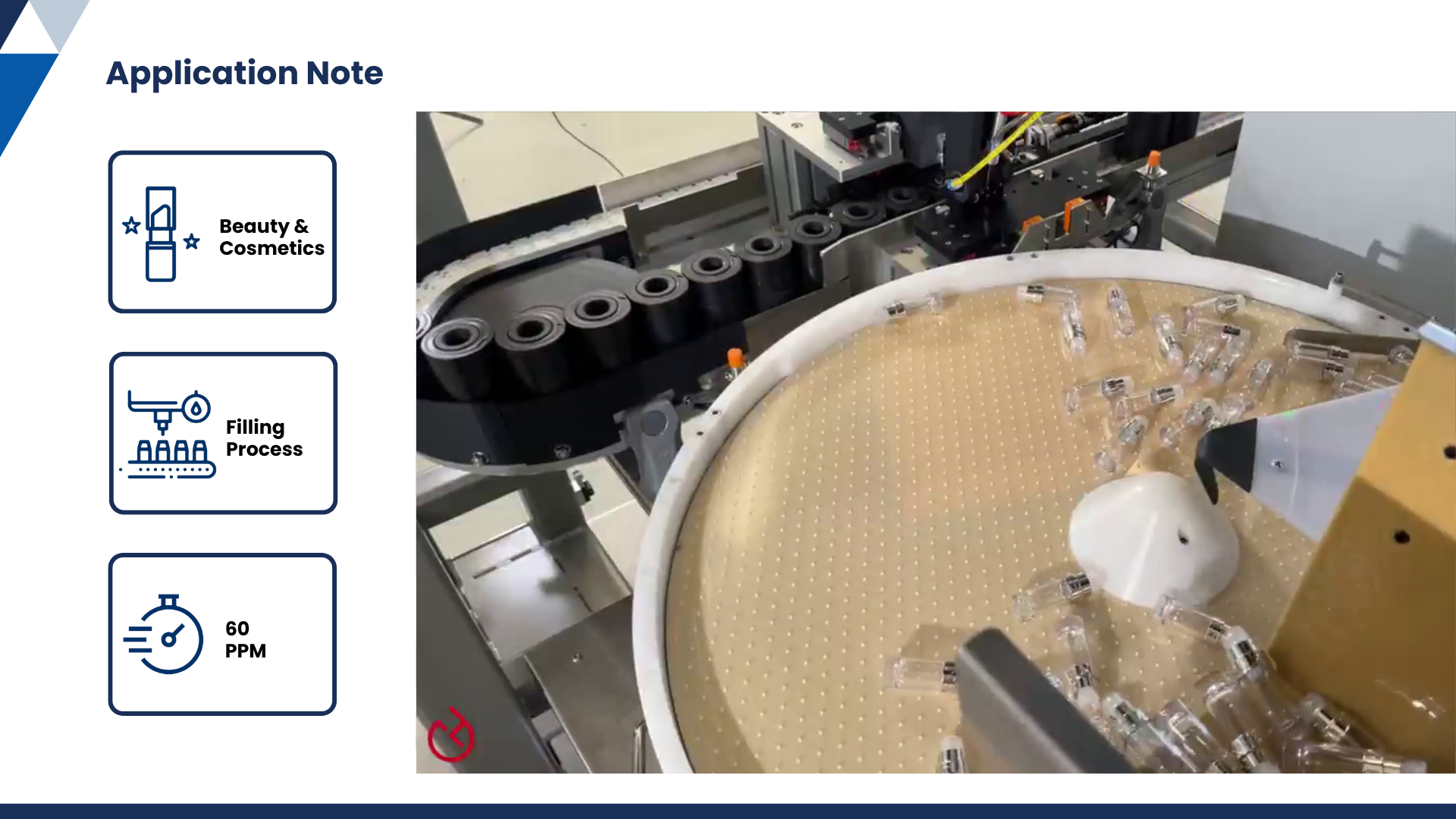

Case Study: Advanced Automation for Perfume Filling and Capping. Precision, Flexibility, and High Productivity with FlexiBowl® and ABB Robotics.

Our Partner

GH Développement designs and manufactures packaging machines for the cosmetics, perfumery, and pharmaceutical industries. The company provides tailor-made solutions for filling, capping, labeling, and assembly, meeting specific production requirements with modular and highly customizable industrial systems.

The challenge

- Handling fragile glass perfume bottles that are prone to rolling and difficult to manage with traditional automation methods.

- Ensuring stable, precise, and fast feeding while minimizing errors and production disruptions.

- Minimizing the risk of damage while meeting the high-quality standards required by the industry.

- Adapting to frequent format changes without long reconfiguration times.

The solution

- FlexiBowl® 800 with Spike Disc: prevents glass bottles from rolling, ensuring stable and secure picking.

- ABB IRB 360 Robot: precisely positions the bottles onto the filling and capping stations.

- Flexible structure: easily reconfigurable to handle different parts on a single line while minimizing downtime.

The benefits

- Speed: fast production with a capacity of 60 bottles per minute.

- Precision: delicate and accurate handling of glass bottles to minimize breakage and waste.

- Flexibility: adaptability to different bottle formats without long setup times.

- Efficiency: reduced downtime and optimized productivity, along with a decrease in material waste.