Discover 4 alternatives for Parts Feeding Systems with our infographic. Optimize production with flexibility and...

Leading Medical Equipment Assembly Solutions Top companies in the medical equipment assembly field are innovating....

GM Automatyka has presented our FlexiBowl solution at ITM Industry Europe in Poznán with their...

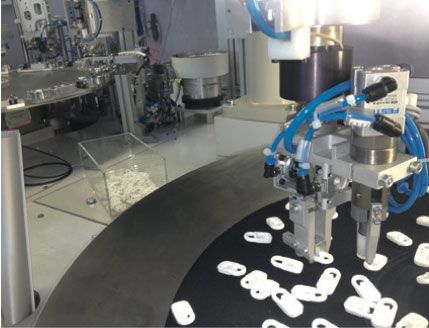

Flexible feeders are vision-based technologies for factory automation that provide manufacturing plants with the possibility...

Vibratory Bowl Feeder: Traditional part feeding system FlexiBowl: the new frontier of feeding systems Comparing...

Total cost of ownership We explain below why FlexiBowl® is a cost-effective solution, according...

What is a SCARA Robot? The SCARA acronym stands for Selective Compliance Assembly Robot...

FlexiVision and FlexiBowl: Powerhouses for Vision-Guided Robots In the fast-paced evolution of industrial automation, vision-guided...

The flexibility of a system describes its ability to adapt to a wide range of...

Integrators who manufacture assembly automation and OEM’s who need equipment to manufacture assemblies are faced...