- Vibratory Bowl Feeder: Traditional part feeding system

- FlexiBowl: the new frontier of feeding systems

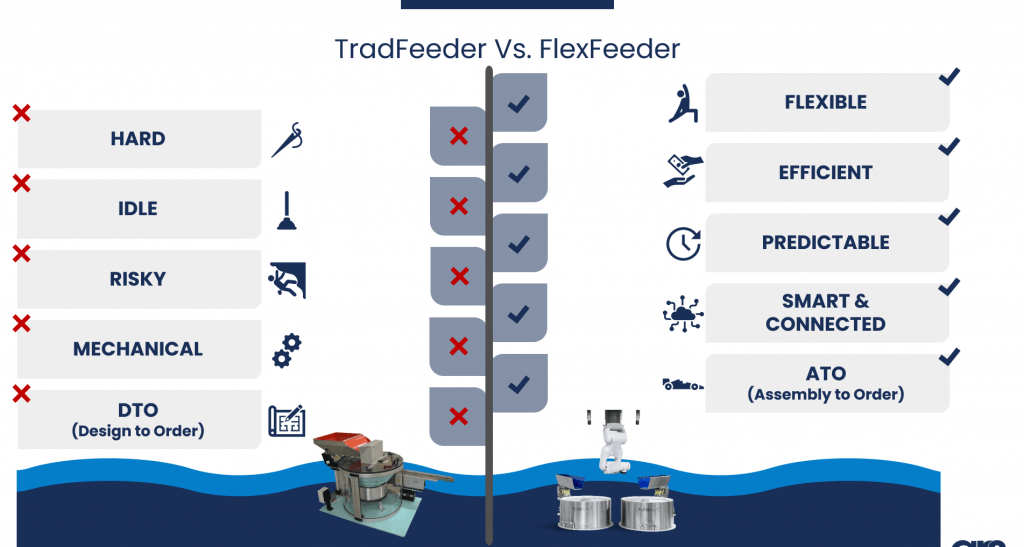

- Comparing FlexiBowl® and Vibratory Bowl feeders

- Vibratory bowl feeders: application fields

- FlexiBowl: the alternative to traditional bowl feeders

- Related articles

Vibratory Bowl Feeder: Traditional part feeding system

Vibratory Bowl feeders are the most common solution to handle and sort bulk products to further processing machinery, packaging and assembling lines. As a dedicated solution, they are designed on your samples and they can reach high productivity level.

When installing a bowl feeder, part orientation is the main matter to think about; shape, parts size, weight and material properties must be taken into account. These operations can require more time than expected: suppliers analysis, bowl design, a feasibility study can take lot of time (and lot of money). But the main problem is that performances and operational data (such as productivity and efficiency) aren’t known until vibratory bowl is completed. In case some changes on the part geometry are introduced during product development, the bowl feeder has to be totally modified, with significant additional costs.

Last but not least, product lifecycle today is too short to waste money for all these actions two-three times a year.

Assembly lines today require an increased level of flexibility that vibrating feeders can’t provide.

Flexible feeders aren’t as expensive as most people think.

A typical feeding unit on an assembly machine, is usually composed of several components: vibrating bowl, linear vibrator, index station, noise insulation cup, pick & place unit, plc, sensors, etc. The whole cost for such a system can be on average, around 20-25k€ or more, if we include the time to design, build and test the whole equipment.

The alternative solution FlexiBowl®, which includes a small scara robot, vision camera, software and FlexiBowl® has an average cost between 25-30k€. Its performances can be verified very quickly and unexpensively. In a matter of minutes the FlexiBowl® system can be set up with your parts and running as well as in the real application.

FlexiBowl® has already provided great solutions in many areas: medical, cosmetic, appliance, automotive, consumer goods, electrical component and so on.

FlexiBowl® is an innovative flexible parts feeder that is replacing vibratory bowl feeders in many applications that require rapid changeover and costant performances with no jams and misfeeds.

FlexiBowl: the new frontier of feeding systems

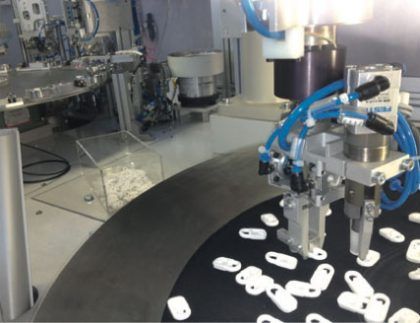

FlexiBowl® is an highly innovative solution that goes beyond the traditional function of vibratory bowl feeders. It does not work with vibration, but through the combined actuation of servomotor and impulse generator. Once bulk components lie on feeder surface with the right orientation, the vision system can locate them and send coordinates to the robot for pick up.

FlexiBowl® is capable of feeding entire families of parts and does not require any retooling cost for product changeovers: product changes can be made in a matter of seconds without any trouble.

Even if vibratory parts feeders have been for a long time a prime instrument for industries, nowadays there is a growing interest for alternative solutions that meet the current industrial needs. FlexiBowl® minimize costs for product changeovers and have no project risk: FlexiBowl® team is available to run preliminary free tests on your samples to verify performances. In a very few minutes the system can be set up to test and verify performance with your sample components.

It may be provided Remote Control & field support via the Web.

Traditional Bowl feeders are normally built to sort a specific component: if any change in dimension occurs in a later stage, the system cannot be used anymore. Burrs or any minimal variation in geometry can affect the overall system performances. With FlexiBowl® you get sort multiple parts. Moreover FlexiBowl® guarantees superior performances and no failure for jams and misfeeds.

Comparing FlexiBowl® and Vibratory Bowl feeders

Vibratory Bowl Feeder: application fields

Bowl feeders are widely used in almost every industry such as pharmaceutical industry, cosmetic, fashion accessories, consumer electronics, automotive, appliance etc.

Bowl Feeders can become a nightmare for production people in many case; examples: plastic parts showing burrs, metal stamped parts with unregular geometry. In such cases, misfeeds and jams bring efficiency parameters down to unacceptable levels.

On the other hand, the performance of FlexiBowl® system is absolutely unaffected by the above problems.

FlexiBowl® represent a great alternative to vibratory bowl feeders in all those areas where flexible production is essential for success. Entire families of parts can be fed with the same system without mechanical retooling; several comparison studies have proven FlexiBowl® to be suitable to feed parts in a more uniform, continuous and efficient way. Parts can be fed in continuous movement, i.e. circular tracking. It is also highly versatile and suitable to feed a wide variety of parts.

FlexiBowl®: the alternative to traditional Bowl feeders

Although most companies are still making a wide use of vibratory bowl feeders, there is a growing interest in alternative solutions that can meet the current industrial need to decrease human control and to decrease maintenance costs.

Moreover, for most companies, the productions volumes are no longer what they used to be in the past while the trend is represented by frequent production changes.

Vibratory feeders are suitable to work in high volume productions which don’t require any product change. If it occurs or it require an incredible waste of time to introduce the necessary modifications. If a possibility to introduce any product change is foreseen, then FlexiBowl® can become the best solution.

It’s competitive in price with traditional parts feeder while representing the best solution for assembly lines where parts change frequently.

FlexiBowl® has become a valid alternative to dedicated solutions on many assembly lines in cosmetic industry, but it also has great and increasing applications in medical, consumer electronics, appliance, automotive fields etc.

Related Articles

- Bowl Feeders - Wikipedia

- Vibratory Feeders - Wikipedia

- Linear Feeder - www.freepatentsonline.com

- Innovative Usage of Vibratory Bowl Feeders – Elscint Automation By Monish Shete23

- [...] While flexibility encompasses every part of the workcell design, inlcuding hardware and control software, the ability to feed partes in a wide variety of sizes and shapes is crucial. Conventional feeding methods, such as vibratory bowl feeders, are not pratical for flexible workcells because of their specialized nature. This system is composed of three conveyors wotking togheter. The first conveyor is inclined and lift parts from a bulk hopper in a semi-singulated manner.

- [...] Flexible parts feeding techniques have begun to gain industry acceptance. However, one barrier to effective flexible feeding solutions is a dearth of knowledge of the under lying dynamics involved in flexible parts feeders. The paper presents the results of testing the CWRU flexible parts feeder. [...] source 1999 IEEE International Conference on Robotics and Automation

- [...] To rapidly feed industrial parts on an assembly line, Carlisle et. al. [4] proposed a flexible parts feeding system that drops parts on a flat conveyor belt, determines their pose (position and orientation) with a vision system and uses a high-speed scara robot to move them to a pallet in a desired pose. [...] source Estimating throughput for a flexible parts feeder, in Exeperimental Robotics.

- Do you need a special automated feeder bowl coating, bowl feeder lining, or a special clean room pharmaceutical grade feeder bowl? We can help with all of those types of feeder bowls and more! Pharmaceutical clean room feeder bowls are a specific area of expertise. [...] source Service Engineering

A typical feeding unit on an assembly machine, is usually composed of several components: vibrating bowl, linear vibrator, index station, noise insulation cup, pick & place unit, plc, sensors, etc.